Pipe Work Systems

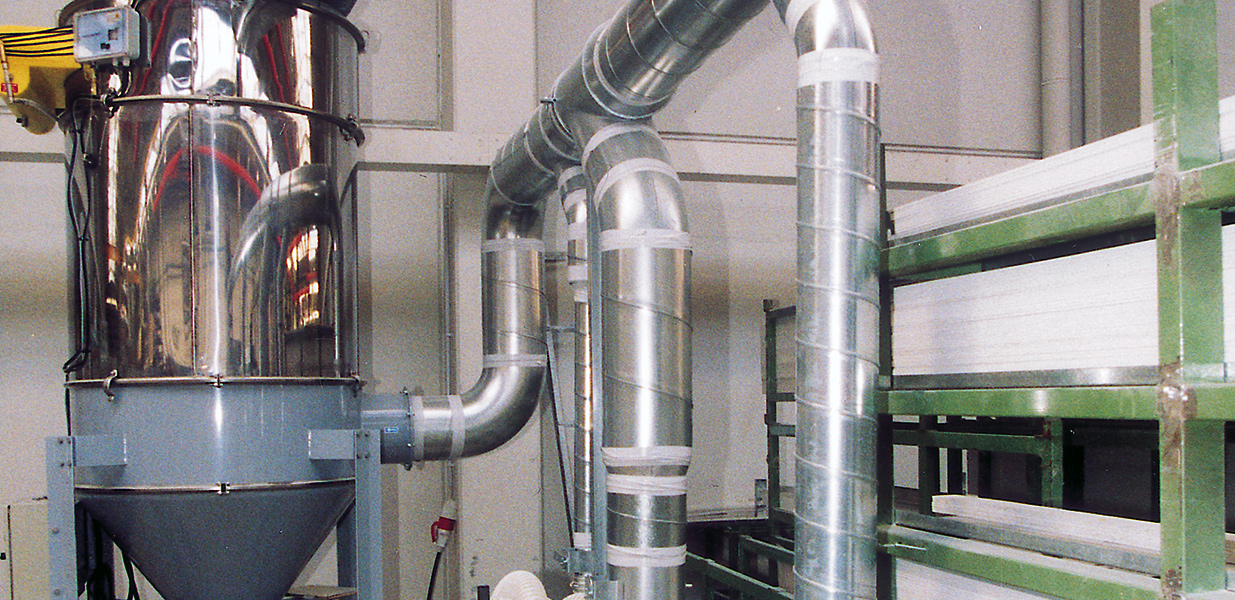

Pipe work systems are an important part of stationary suction and dust extraction units. But also mobile industrial vacuum cleaners and mobile suction units develop their full potential only when connected to a dedicated fixed pipe work system. These semi-stationary suction units as they are called, combine the best of two worlds: The comfort and efficiency of a fixed pipe work system on the one hand, and the flexibility of a mobile unit which can also be used independently from the pipe work system if the requirement arises on the other hand. To design customized semi-stationary suction systems is a specialty of Wieland and is part or our reputation.

The correct design and dimensioning of the pipe work system is crucial to the overall performance of the suction system. With our team of experienced pipe work engineers, we make sure that the pipe work system is designed to maximize performance and efficiency of our suction units.

Choice of System

We propose three different pipe work systems in order to be able not only to offer the technically best system but also the most cost-effective one:

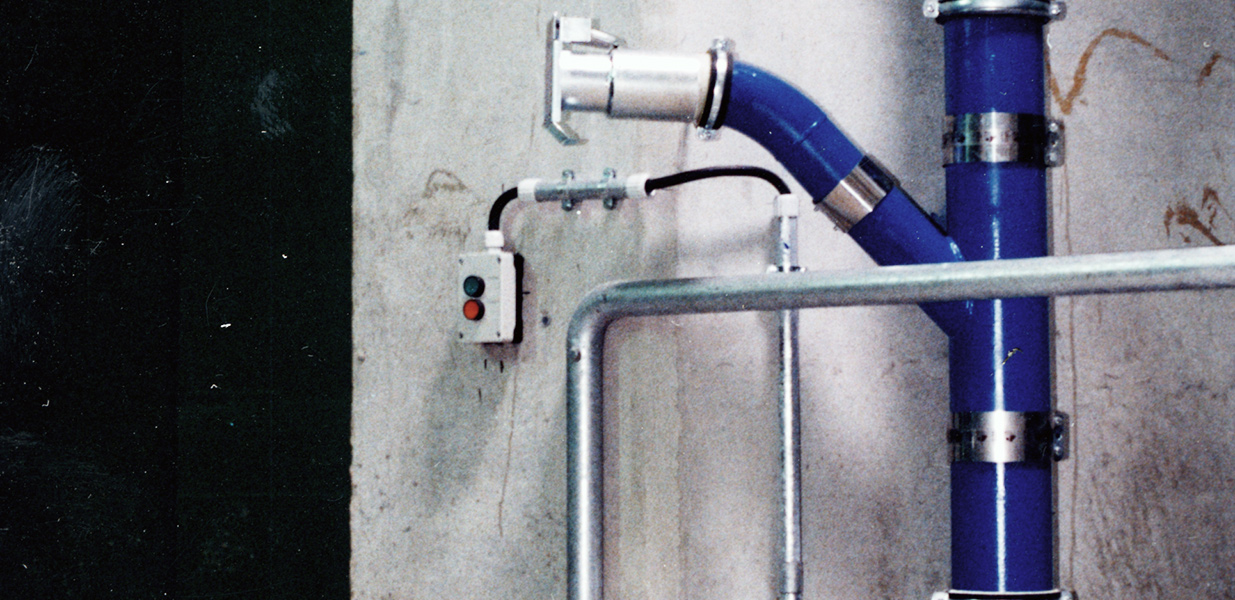

Pipe work system WF: DN 80 to DN 300, designed for light dust extraction applications. Available in galvanized version.

Pipe work systems SP: DN 80 to DN 300, designed for all dust extraction applications and for vacuum cleaning applications with non-abrasive suction materials and short to medium-ranged suction distances. Available in primed, galvanized and stainless steel versions.

Pipe work system MV: DN 50 to DN 150, designed for all dust extraction, vacuum cleaning and vacuum conveying applications and for long suction distances. Designed and manufactured to the highest Wieland standards. Available in primed, galvanized and stainless steel versions.

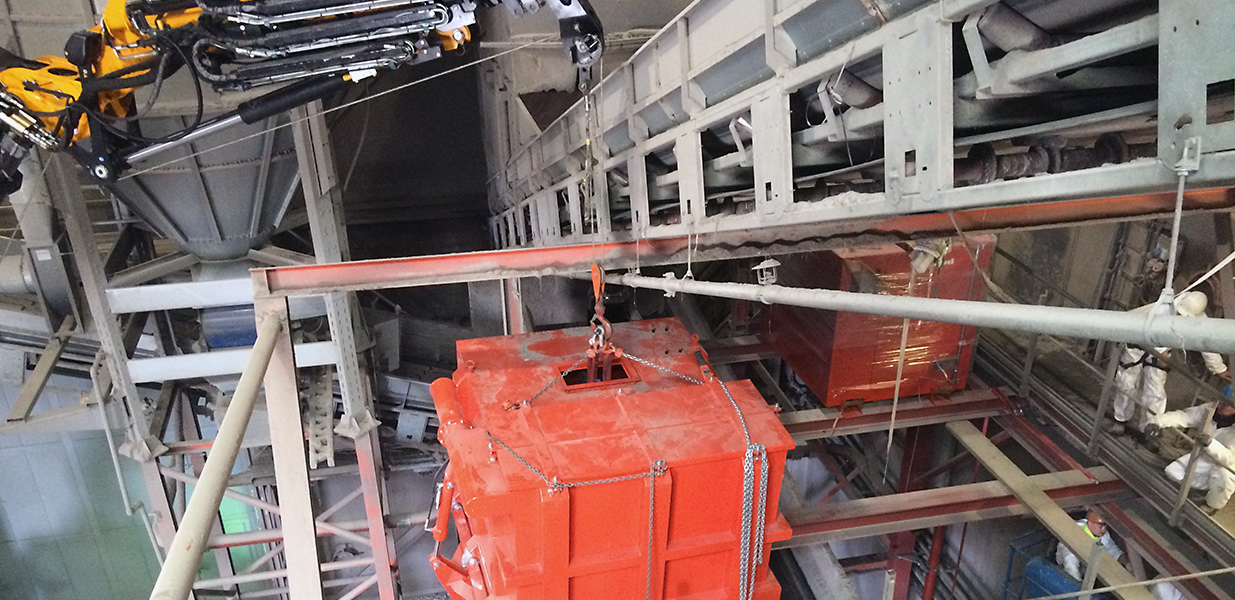

Installation Work

Pipe work systems and stationary suction units need to be installed in our customers’ premises. Wieland can offer this with experienced engineers and service technicians. We are able to handle large projects in a safe and professional way e.g. vacuum cleaning systems for coal fired power plants.

Suction tools

Users frequently underestimate how important it is to make the right choice of suction hoses and suction nozzles in order to achieve good cleaning and conveying results. Wieland offers different accessory systems so that our customers can cope with all types of suction applications. But not only the right choice of suction diameter and type of nozzle is decisive. We have invested many years of experience to develop high-grade suction hoses. Your suction material may be hot, abrasive or corrosive – we have always the right type of suction hose for your application.

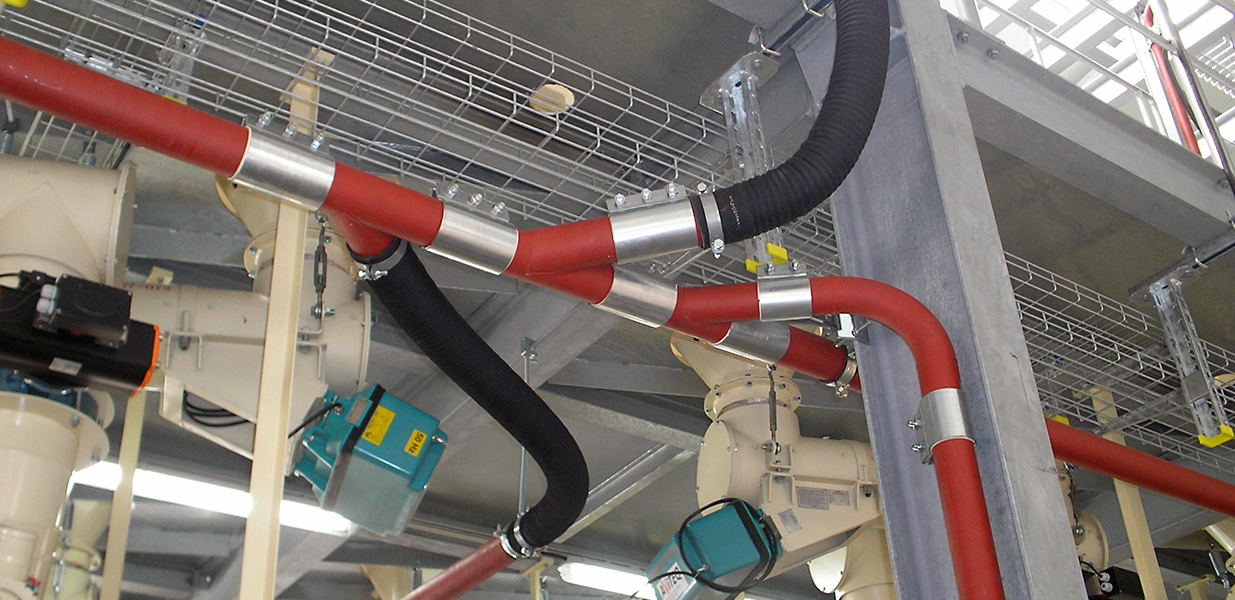

Accessory system type K: DN 40, 50 and 60. Designed for vacuum cleaning and vacuum conveying applications with small suction hose diameters. All components are appropriate for Atex applications.

Accessory system type MV: DN 80 and 100. Designed for vacuum cleaning applications with large suction hose diameters and for light conveying applications. Alle components are appropriate for Atex applications.

Accessory system type SK: DN 80, 100, 125 and 150. Designed for heavy duty vacuum conveying applications. Robust, reliable Wieland quality. All components are appropriate for Atex applications.